In hazardous environments, the integrity of sealing solutions can mean the difference between safe operations and catastrophic failures. Roxtec has established itself as a leader in providing sealing solutions that significantly enhance safety standards across various high-risk industries. This article delves into the essential role of Roxtec seals in maintaining safety and operational continuity in such environments.

Unmatched Protection Against Multiple Risks

Roxtec seals are engineered to address the complex challenges posed by environments where the risk of fire, explosions, and water ingress are ever-present. The design and materials used in Roxtec sealing systems provide superior resistance against fire, ensuring that they can withstand extreme temperatures while preventing the spread of flames and smoke. This is particularly critical in industries like oil and gas, where the potential for fire hazards is high.

Sealing Out Water and Moisture

Water ingress can lead to significant damage in electrical systems and compromise the structural integrity of facilities. Roxtec’s waterproof sealing solutions are designed to withstand high-pressure environments, making them ideal for subsea applications, as well as flood-prone areas. By providing a tight and durable seal, Roxtec prevents moisture and water from penetrating critical junctions, thus protecting equipment and ensuring the safety of the personnel.

Chemical Resistance for Harsh Conditions

In chemical manufacturing and processing, seals are exposed to a variety of corrosive substances. Roxtec’s chemical-resistant seals are crafted to withstand harsh chemicals, thus maintaining their sealing integrity over time. This resistance ensures that harmful gases and liquids are contained, which is essential for both environmental protection and worker safety.

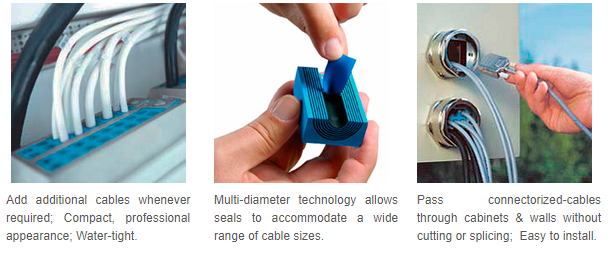

Customizable Solutions for Precise Fit

One of the standout features of Roxtec’s sealing solutions is their adaptability. The modular design allows for customization to fit cables and pipes of varying diameters, ensuring a tight seal even in the most challenging conditions. This flexibility is not only crucial for maintaining safety but also simplifies installation and maintenance, reducing downtime and operational costs.

Certified for Safety

Roxtec’s commitment to safety is backed by rigorous testing and certifications. Their products meet global safety standards, including those set by ATEX and IECEx for explosive environments. Such certifications reassure facility managers and engineers of the reliability and safety of Roxtec seals, facilitating their widespread adoption in hazardous settings.

Conclusion

In hazardous environments, every component of a facility must be designed to ensure maximum safety and reliability. Roxtec’s sealing solutions play a pivotal role in achieving these safety standards. With their advanced fireproof, waterproof, and chemical-resistant properties, Roxtec seals provide peace of mind, knowing that critical systems are protected against a multitude of threats. As industries continue to face complex safety challenges, Roxtec’s innovative solutions stand as a testament to their commitment to enhancing safety where it matters most.